Laser scanning has become an essential technology for the modernization and maintenance of industrial buildings. Thanks to point clouds, this tool allows for the capture of highly accurate three-dimensional data, optimizing design, renovation, and maintenance processes. In this article, we explore the advantages of laser scanning in industrial buildings and how its integration with point clouds revolutionizes the sector.

Learn how we apply this technology on our point cloud and 3D design page.

What is laser scanning and how does it work?

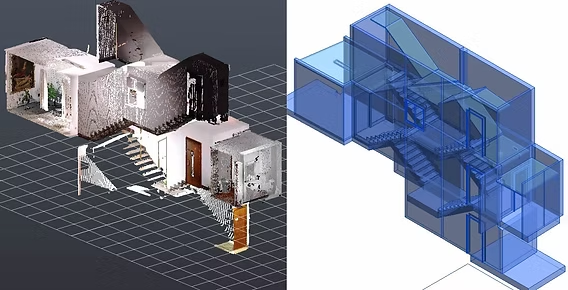

Laser scanning uses advanced technology to capture three-dimensional data of a structure. It works by emitting a laser beam that measures distances and generates an accurate digital representation of the industrial facility. This representation, known as a point cloud, includes millimeter-level details that allow for:

- Model structures in 3D.

- Detect deformations or damage.

- Plan renovations or modifications accurately.

Advantages of laser scanning in industrial warehouses

1. Millimeter precision

Laser scanning captures details that would be impossible to measure manually, ensuring a complete and accurate view of the structure.

2. Integration with BIM and other tools

The data obtained is easily integrated with BIM models, facilitating 3D planning and design.

Advantages of this integration:

- Conflict identification before construction or rehabilitation.

- Detailed visualization of each structural element.

- Optimization of resources and time in the project.

3. Predictive maintenance and rehabilitation

Laser scanning allows for early identification of incidents, facilitating preventative maintenance and extending the life of the ship.

If you're considering a renovation project, check out our industrial warehouse renovation service.

Applications of laser scanning in industrial buildings

1. Design of new structures

Laser scanning provides a precise basis for the design of new industrial buildings, ensuring that specifications are accurate and that the project meets the highest safety standards.

2. Rehabilitation of existing structures

A detailed analysis of an existing structure facilitates the planning of interventions such as roof repairs or the adaptation of spaces for new industrial activities.

Discover how we integrate this technology into our projects on our industrial warehouse page.

3. Preventive maintenance

It allows the condition of a ship to be assessed regularly, helping to prevent problems before they become serious structural failures.

4. Compatibility with advanced technologies

In addition to BIM, laser scanning data is compatible with structural analysis and simulation tools, enhancing design and planning processes.

See how we apply these advanced technologies on our page. structural calculation.

Common mistakes when using laser scanning

- Incomplete data capture: It is essential that the scan covers all critical areas of the structure.

- Lack of integration with BIM: Failure to leverage this technology limits its true potential.

- Lack of trained professionals: Incorrect data analysis can lead to errors in design or planning.

How we implemented laser scanning at Engind

At Engind, we use laser scanning to ensure maximum precision for every project. Our process includes:

- Data capture: High-precision three-dimensional survey using laser scanning.

- Analysis and processing: Creation of the point cloud and integration with BIM models.

- Planning and execution: Using data to efficiently design, rehabilitate, or maintain structures.

Check out our projects on our industrial warehouse page to learn about real-life examples of how we've applied this technology.

Innovation with laser scanning and point cloud

Laser scanning and point clouds are key tools for optimizing the design, renovation, and maintenance of industrial buildings. These technologies not only ensure precision but also enable more sustainable and efficient project planning.

At Engind, we specialize in integrating laser scanning and point clouds into industrial warehouse projects. Discover how we can help you implement these advanced solutions in your project.