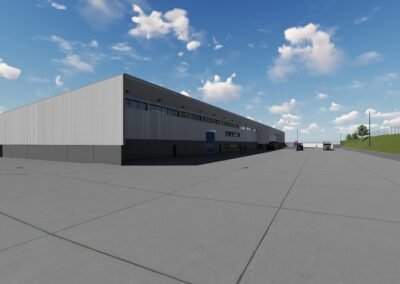

ARTYPLAST is a company with more than three decades of experience in the rotomolding sector. To preserve its leading position and continue offering high quality products to its customers, ARTYPLAST decided to expand its facilities and ENGIND, an engineering company specialized in industrial projects, had the privilege of collaborating on this project.

ENGIND Engineering company specialized in industrial projects

Formalities:

Industrial installation involves a series of bureaucratic procedures, especially when it comes to municipal permits and licenses. Engind took on the task of managing all the paperwork at the town hall on behalf of ARTYPLAST, allowing the company to focus on its core operation while the process progressed smoothly.

One of these steps is the communication of the start of activity to the City Council, a fundamental step to guarantee that the activities are carried out in accordance with current regulations and without legal setbacks. Engind took responsibility for carrying out this process, ensuring that ARTYPLAST was in compliance with all regulations.

Calculation of facilities:

A critical aspect of the ARTYPLAST installations was the calculation and installation of the fire protection installations. Engind applied its experience in facilities engineering to design an effective and safe one.

Likewise, to maintain a high level of production and ensure that the new storage area was fully operational, ARTYPLAST needed a significant expansion of its electrical installation. Engind designed and supervised the implementation of this expansion, ensuring that ARTYPLAST had the necessary electrical power for its current and future operations.

Conclusions: A Successful Collaboration

The project for ARTYPLAST has been a clear example of a successful collaboration between a leading rotomolding company and an experienced engineering company like Engind.

Engind's commitment to engineering excellence has allowed ARTYPLAST to continue to stand out in the rotational molding industry nationwide. We are proud to have been part of this project and we hope to continue collaborating with ARTYPLAST in their future expansion and improvement projects.